TAGEX RUBBER PADS

for machinery operating at weights of between 15 and 25 tons

Pad systems are becoming increasingly popular, and for a good reason, as TAGEX pads break the limitations of current steel track undercarriages. The use of this pad system opens up totally new areas of application especially for machinery operating at weights of between 15 and 25 tons.

From now on, this machinery can be used in sensitive areas where conventional steel tracks would cause too much noise and damage, such as on inner-city roads and squares.

Bolt On Type + Clip On Type + Chain On Type

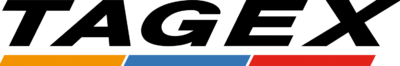

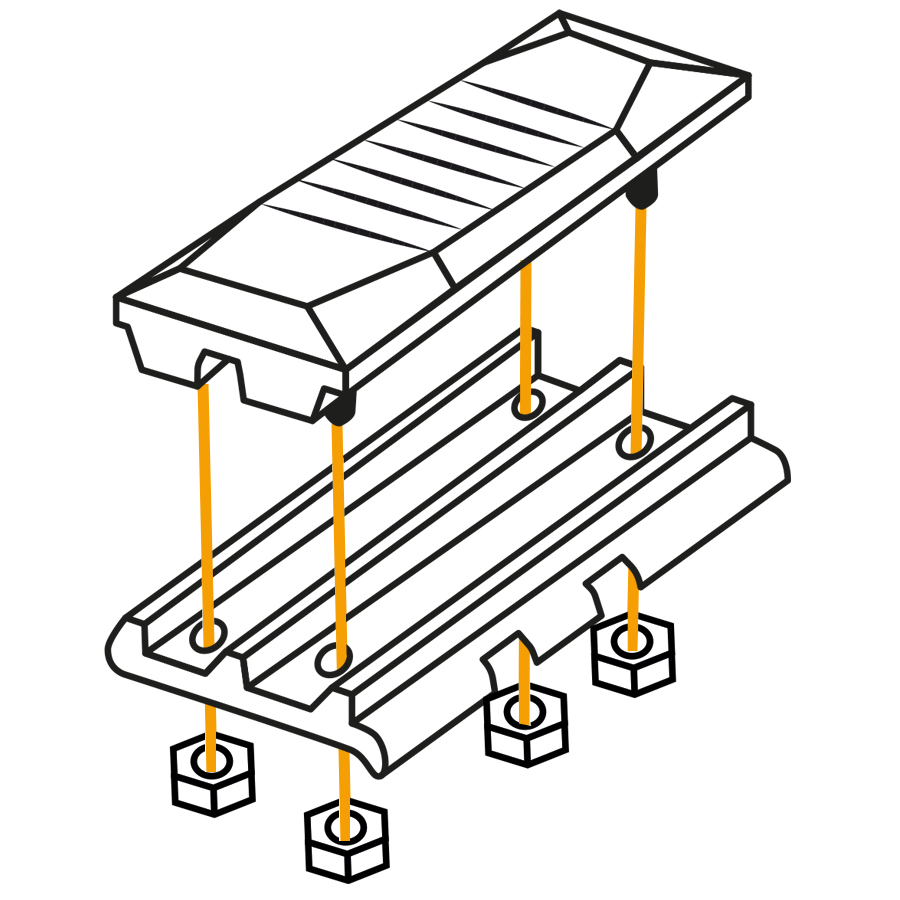

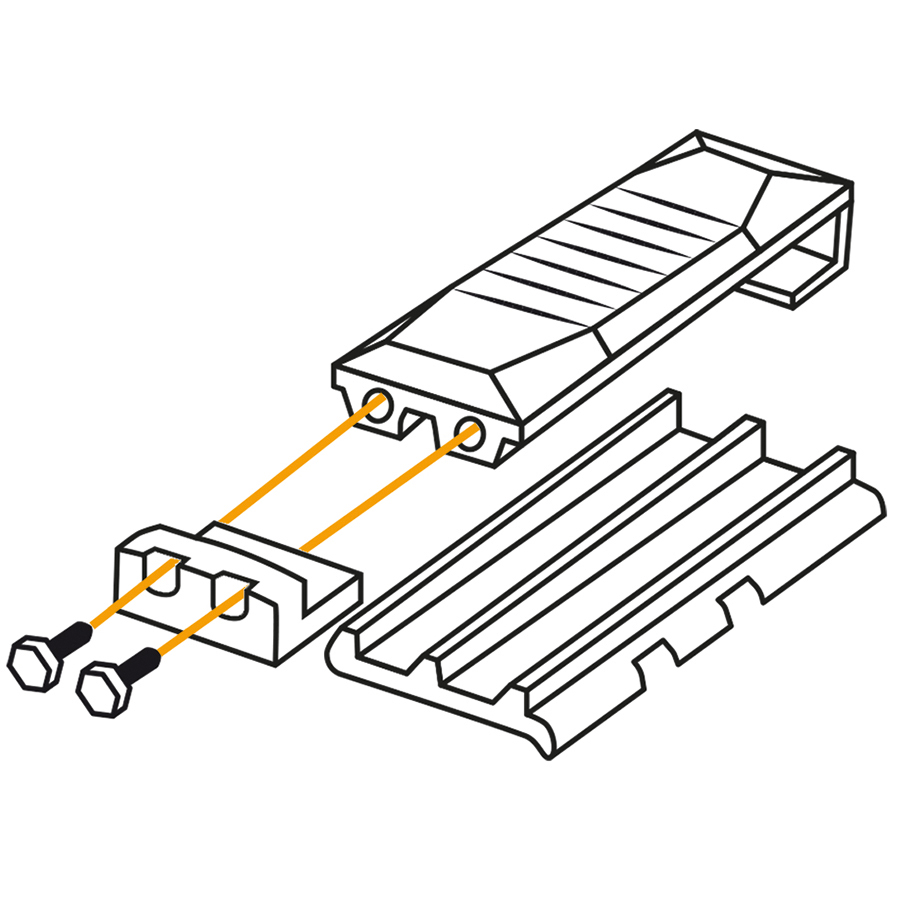

THERE ARE THREE BASIC RUBBER PAD SYSTEMS

Whilst so-called Bolt On Pads can be bolted onto the steel base plates of the steel track retrospectively, Chain On Pads are bolted onto the base of the track instead of the steel base plate. Clip On Pads are similar to Bolt On Pads; the two systems simply differ in the method used for installation. TAGEX stocks an extensive range of Chain On Pads. An entire range of Bolt On Pads is also available, but not ex stock (i.e., approx. 10-week lead time from receipt of order).

TAGEX PADS EXCEL IN PARTICULAR IN

easy handling

Defective TAGEX pads can be changed individually.

longer life

Steel tracks with TAGEX pads have a longer service life than rubber tracks and will not tear.

High-strength steel alloys

High-strength steel alloys

High-quality rubber compounds

High-quality, extremely adhesive, and wear-resistant rubber compounds

modern design

A modern design that uses round, level edges to counteract potential damage from shear forces when turning on the spot.

triple grouser structure

A sophisticated triple grouser structure, giving the steel base excellent stability and providing the rubber body with a high level of adhesive surface.

A note on the correct area of application

Rubber pads are versatile. But the robust TAGEX rubber pads are also rubber products for which applications in demolition, rubble and recycling material are poison. Machines on TAGEX rubber pads feel most at home on level ground with a hard surface.