TAGEX – SKID STEER LOADER TRACKS

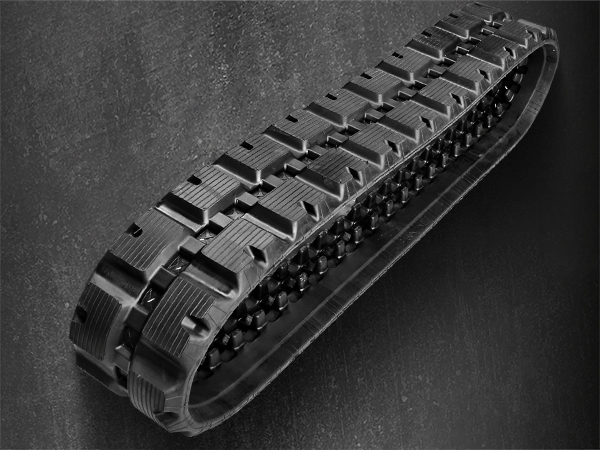

For

- Compact Terrain Loader

- Multi Terrain Loader

- Mini Loader

- Micro Loader

As loaders are moving permanently, this type of track is by far the most demanding of the rubber tracks applications. The capability of a loader track quickly becomes obvious due to the following aspects: high speeds, constant changes of direction, slips when loading buckets, as well as the loaders’ increasing operating weights, motor and hydraulic power. DRB SPEED- and NMC-series loader tracks use particularly abrasion- and tear-resistant rubber compounds. The interior steel cords are jointless. Contrary to competing production processes using jointless bands, DRB SPEED- and NMC-series tracks are produced by barrel plating using just a single vulcanisation process.

This unique manufacturing method, together with high-quality rubber compounds, ensures that DRB products occupy an absolutely exceptional position worldwide. For example, DRB loader tracks usually achieve 400 percent more operating time than a no-name product. The gap between DRB loader tracks and other brands is significant and was proven using internal benchmarks. At a slightly higher price than your average product, and considering their extended operating time, DRB loader tracks offer extremely good value for money, enabling you to minimise your machine’s operating costs. A product for true professionals.